A new website forum and LinkedIn Group have been created to communicate and discuss developing media technology, production issues within your print operations, best practices and operational issues among the newspaper industry operations and technology community.

LINKS:

Newspaper Media Technologies Forum

http://groups.google.com/group/newspaper-technologies

LinkedIn Group

http://www.linkedin.com/e/gis/93001/3D9C8C1B3829

In order for these sites to be successful, they must be established as the credible source for valuable information and collaboration for the newspaper operations and technology development community.

Tuesday, June 24, 2008

Monday, June 23, 2008

NAA: Change for an Industry

It's 2PM and the phone is ringing at NAA.... the phone is answered by an unfimilar voice. After months of staffers heading for the door, NAA's employee "buy-out" last week had 15 senior managers and staffers packing their boxes. But it's the calm before this week's storm, when an unknown number of staff will abruptly have to pack their boxes and head for the door. NAA is feeling their member's pain this month as the association reorganizes.

While the headlines about the health of the newspaper industry are polarized, the facts are clear. From some perspectives, the newspaper industry is on the rocks; shedding jobs like a Husky in July, newsprint consumption is falling by double-digits, major newspaper corporations facing substantial reductions in revenue and soft advertising volume. But take a long hard look at the desire for news today; electronic gadgets, Internet and digital printing are driving the public's desire for news to record heights. People want to be informed 24/7, not just over a cup of morning coffee. Newspapers are not longer a one trick pony, they are a multi-media. So where does that leave the newspaper association?

In most crisis, the association leads the change and rallies the members to the new pinnacle of their industry with leadership and tools to directly assist members thought the tough business environment. And I'm sure the leaner, more focused newspaper association will take that charge.

The newspaper industry is in survival mode today.

Tactics that the newspaper association developed to garner advertising and assisted members to build revenue in the past, have lost their effectiveness. The weird space characters that manned the industry ads are now just awkward icons. The newspaper industry is in an identity crisis as they develop a multi-media strategy. The reorganized NAA should develop tools and strategies to position the newspaper as the central source for information in the community, using technology to create tools that enable members to build the multi-media platforms (or at least understand the parameters), and understanding how to capitalize on digital technology.

The future vision of the newspaper industry must be about building a multi-media industry; with a full compliment of print and on-demand information and targeted advertising, marketing capabilities and enabling communication for advertisers. Newspapers are by nature a local product, so the newspaper association must assist in position the newspaper as the new multi-media source in the community.

While the headlines about the health of the newspaper industry are polarized, the facts are clear. From some perspectives, the newspaper industry is on the rocks; shedding jobs like a Husky in July, newsprint consumption is falling by double-digits, major newspaper corporations facing substantial reductions in revenue and soft advertising volume. But take a long hard look at the desire for news today; electronic gadgets, Internet and digital printing are driving the public's desire for news to record heights. People want to be informed 24/7, not just over a cup of morning coffee. Newspapers are not longer a one trick pony, they are a multi-media. So where does that leave the newspaper association?

In most crisis, the association leads the change and rallies the members to the new pinnacle of their industry with leadership and tools to directly assist members thought the tough business environment. And I'm sure the leaner, more focused newspaper association will take that charge.

The newspaper industry is in survival mode today.

Tactics that the newspaper association developed to garner advertising and assisted members to build revenue in the past, have lost their effectiveness. The weird space characters that manned the industry ads are now just awkward icons. The newspaper industry is in an identity crisis as they develop a multi-media strategy. The reorganized NAA should develop tools and strategies to position the newspaper as the central source for information in the community, using technology to create tools that enable members to build the multi-media platforms (or at least understand the parameters), and understanding how to capitalize on digital technology.

The future vision of the newspaper industry must be about building a multi-media industry; with a full compliment of print and on-demand information and targeted advertising, marketing capabilities and enabling communication for advertisers. Newspapers are by nature a local product, so the newspaper association must assist in position the newspaper as the new multi-media source in the community.

Thursday, June 19, 2008

Beyond LEAN: Trust your instincts

Developing a bone-deep understanding of your operations by honing intuitive talents.

Seasoned managers seem to develop a sixth sense — an instinctive way to evaluate performance and operating conditions based on staff mood changes or variations in the sound of equipment that’s operating.

Metrics are considered essential to any quality or performance management program today. Such metrics commonly utilize LEAN principles to assess operational efficiency by objectively evaluating data that’s gathered and poured into spreadsheets, graphs and efficiency reports. This process measurement is important in determining what really needs to be improved.

Some managers, though, take a step back from the metrics and use what might be called a sixth sense — an instinct — to gauge their operation’s performance. In his book Blink, Malcolm Gladwell examines this kind of intuitive knowing. He reports about how our minds process information; dovetailing nicely with getting the most out of LEAN manufacturing principles and metrics.

In a LEAN manufacturing environment, work should flow smoothly between departments and processes, without special or exception processing or delays. A benefit of a LEAN-oriented workplace is that while metrics are important, you don’t need complex statistical analyses to recognize improvement opportunities. What you do need to is an understanding of your operation’s optimal operating characteristics, and your understanding of it needs to be bone-deep.

Gladwell points out that this kind of information-gathering is crucial if you want to strengthen your ability to separate important information from the “noise” that comes at us daily. He calls this “thin-slicing.” He also notes that the ability to sift out significant detail is one you can learn.

Developing your sixth sense should start with a slow walk through your operation, keeping in mind that the LEAN production operations goal is to be well-organized and efficient. Consider this field work and realize that it’s as important to focus on what you don’t see as on what you can directly observe.

No waste or red ink: The work environment is clean, well organized and logically designed. Machine controls are identical for all identical equipment, independent of vintage. Work instructions are comprehensive and identical for all jobs. Waste is identified and disposed of before it accumulates. Both materials and information flows easily and rapidly through the process.

No searching or wandering: Everyone should have the tools and materials available for the job. Tools should be organized and employees should use the right tool for the job. 5S principals are an excellent way to organize the work environment.

No delays or waiting for materials: Work should flow through the process; no one should be waiting for materials, people or paperwork to arrive on time. The JIT principals can organize workflow to deliver materials to the right place, at the right time.

No special processing or guesswork: Work is standardized and displayed. All the information for people to effectively do their job is available, accurate and complete.

No detours or obstacles: Everyone has a clear idea of the workflow and process. Employees have a clean work environment. Walk ways and work areas enable a straight shot to get between points. People should not have to walk around equipment, people, racks or materials.

No extraneous stuff: Work areas should contain the tools, materials and equipment for the job – no less or no more.

No injuries: All injuries are preventable. Injuries are typically the result of rushing, cluttered work environment or using the wrong tool for the job. Safety procedures must be built into the work processes. A comprehensive safety program and daily safety meetings emphasize the importance of safety and keep employees accountable for a safe work environment.

The information you gain by directly observing the performance and flow of work in your operations can be used to validate collected process data and statistical analyses. Others may see your abilities as “magic,” but it’s really a matter of developing the “sixth sense” all of us have.

Seasoned managers seem to develop a sixth sense — an instinctive way to evaluate performance and operating conditions based on staff mood changes or variations in the sound of equipment that’s operating.

Metrics are considered essential to any quality or performance management program today. Such metrics commonly utilize LEAN principles to assess operational efficiency by objectively evaluating data that’s gathered and poured into spreadsheets, graphs and efficiency reports. This process measurement is important in determining what really needs to be improved.

Some managers, though, take a step back from the metrics and use what might be called a sixth sense — an instinct — to gauge their operation’s performance. In his book Blink, Malcolm Gladwell examines this kind of intuitive knowing. He reports about how our minds process information; dovetailing nicely with getting the most out of LEAN manufacturing principles and metrics.

In a LEAN manufacturing environment, work should flow smoothly between departments and processes, without special or exception processing or delays. A benefit of a LEAN-oriented workplace is that while metrics are important, you don’t need complex statistical analyses to recognize improvement opportunities. What you do need to is an understanding of your operation’s optimal operating characteristics, and your understanding of it needs to be bone-deep.

Gladwell points out that this kind of information-gathering is crucial if you want to strengthen your ability to separate important information from the “noise” that comes at us daily. He calls this “thin-slicing.” He also notes that the ability to sift out significant detail is one you can learn.

Developing your sixth sense should start with a slow walk through your operation, keeping in mind that the LEAN production operations goal is to be well-organized and efficient. Consider this field work and realize that it’s as important to focus on what you don’t see as on what you can directly observe.

No waste or red ink: The work environment is clean, well organized and logically designed. Machine controls are identical for all identical equipment, independent of vintage. Work instructions are comprehensive and identical for all jobs. Waste is identified and disposed of before it accumulates. Both materials and information flows easily and rapidly through the process.

No searching or wandering: Everyone should have the tools and materials available for the job. Tools should be organized and employees should use the right tool for the job. 5S principals are an excellent way to organize the work environment.

No delays or waiting for materials: Work should flow through the process; no one should be waiting for materials, people or paperwork to arrive on time. The JIT principals can organize workflow to deliver materials to the right place, at the right time.

No special processing or guesswork: Work is standardized and displayed. All the information for people to effectively do their job is available, accurate and complete.

No detours or obstacles: Everyone has a clear idea of the workflow and process. Employees have a clean work environment. Walk ways and work areas enable a straight shot to get between points. People should not have to walk around equipment, people, racks or materials.

No extraneous stuff: Work areas should contain the tools, materials and equipment for the job – no less or no more.

No injuries: All injuries are preventable. Injuries are typically the result of rushing, cluttered work environment or using the wrong tool for the job. Safety procedures must be built into the work processes. A comprehensive safety program and daily safety meetings emphasize the importance of safety and keep employees accountable for a safe work environment.

The information you gain by directly observing the performance and flow of work in your operations can be used to validate collected process data and statistical analyses. Others may see your abilities as “magic,” but it’s really a matter of developing the “sixth sense” all of us have.

Friday, June 13, 2008

Planning for the Unexpected - Part 3

It is relatively easy to convenience yourself that disasters won't happen in our town or to our business; it's would turn even the seasoned Publisher or Production Director into a nervous wreck to constantly be thinking about "what if''s". Even though the probability of a disaster, such as flood or fire, are very low, every business should have a Continuity of Operations Plan, also called a Business Continuity Plan or Disaster Plan, to be prepared when an event occurs.

An "event" is not always a regional disaster or event that makes front page news, it could be as simple as a power outage or loss of water to the building. Losing electricity and water to the building will bring production to a stop just as fast as a flood, fire, or earthquake.

The Continuity of Operations Plan (COOP) is your organizations plan, roles and responsibilities to reestablish operations of essential functions at an alternate location within a reasonable time, and for most daily newspapers the timing is 8-12 hours.

The first step in establishing your COOP is to identify and prioritize your business functions. Think of this as the core business functions that must continue under a broad range of circumstances. For a newspaper, the essential function is publishing the daily edition. Utilize your managers and staff to document the essential functions and then prioritize which functions must be done.

There are many operational benefits from COOP planning in addition to emergency preparedness:

1. Ability to anticipate events and necessary response actions.

2. Adapt to sudden changes in business conditions.

3. Improve performance through identification of essential functions, work processes and communication methods.

4. Improve management controls by establishing measures of performance.

5. Improve communication to support essential functions.

It is essential that once you develop your COOP plan, a'' employees are trained to execute the plan and a communication network is established. Even basic basic communication can be neglected in a pressing situation. A communication plan for employees should include:

1. Regular training and communication with employees on the COOP and business communications plan.

2. Include procedures for securing the work site and to notify key emergency, management and COOP management personnel.

3. Include instructions to employees through a centralized website or phone system, updating status of business units and where staff should report for work.

In the event of a COOP situation, it is important that all employees contact their family members to ensure them that they are safe.

An "event" is not always a regional disaster or event that makes front page news, it could be as simple as a power outage or loss of water to the building. Losing electricity and water to the building will bring production to a stop just as fast as a flood, fire, or earthquake.

The Continuity of Operations Plan (COOP) is your organizations plan, roles and responsibilities to reestablish operations of essential functions at an alternate location within a reasonable time, and for most daily newspapers the timing is 8-12 hours.

The first step in establishing your COOP is to identify and prioritize your business functions. Think of this as the core business functions that must continue under a broad range of circumstances. For a newspaper, the essential function is publishing the daily edition. Utilize your managers and staff to document the essential functions and then prioritize which functions must be done.

There are many operational benefits from COOP planning in addition to emergency preparedness:

1. Ability to anticipate events and necessary response actions.

2. Adapt to sudden changes in business conditions.

3. Improve performance through identification of essential functions, work processes and communication methods.

4. Improve management controls by establishing measures of performance.

5. Improve communication to support essential functions.

It is essential that once you develop your COOP plan, a'' employees are trained to execute the plan and a communication network is established. Even basic basic communication can be neglected in a pressing situation. A communication plan for employees should include:

1. Regular training and communication with employees on the COOP and business communications plan.

2. Include procedures for securing the work site and to notify key emergency, management and COOP management personnel.

3. Include instructions to employees through a centralized website or phone system, updating status of business units and where staff should report for work.

In the event of a COOP situation, it is important that all employees contact their family members to ensure them that they are safe.

Thursday, June 12, 2008

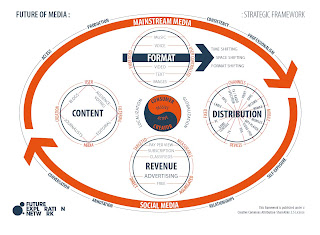

Future Digital Multi-Media Platform

The next generation of information dessimination is rapidly approaching; but the framework is still under construction. The lines between newspaper operations and multi-media will be blurred as the local newspapers become the 24/7 news source for their local markets.

The next generation of information dessimination is rapidly approaching; but the framework is still under construction. The lines between newspaper operations and multi-media will be blurred as the local newspapers become the 24/7 news source for their local markets.The consumer is becoming more digital savvy and expects custom content delivered when, where and how they want it. Consumers will utilize the newspaper customer database to create custom profiles; detailing their interests and and locations throughout the day. Visualize a multi-pane window - each pane is a different view of the world and contains specific content that is important to the customer at that time. For example, the 6am view has overnight news updates and traffic reports, where as the afternoon view has closing stock prices and school updates. Content can be taylored, highlighting baseball only during the season and advertising for specific pending purchases or ongoing consumer items, like the local grocery store specials.

The news media platform will be dynamic and a 24/7 streaming information source. Tayloring content and information as updates occur and into a morning print product to be delivered to the driveway, local home printer or epaper device.

Publishers and media companies need to think about building the centralized content database today - to store and retreave information dynamically as a product or individual profile queries the information.

Wednesday, June 11, 2008

Variable Data and Digital Printing

A buzz from DRUPA has been the new generation of digital web printing, it seems that it's not just for statement printing anymore. Digital web printing is branching out to commercial and newspaper applications and several OEM's are looking at the newspaper market to establish their niche.

Since the early 1900's, newspapers have been produced on high speed web presses that crank out thosands of the same product and have only gotten faster as the newspaper industry rolled into the 21st century. The newspaper industry's transition to color in the 1980's also redefined the industry and newspapers continue to add capacity or reconfigure equipment to deliver full-color advertising.

Technology today is adding a relatively new capability for digital web printing; variable content. Variable data printing isn't exactly new, but the expansion of the forms and statement printing platforms into digital web printing capabilities for newspapers and commercial printers is new.

The newspaper market is squarely in the cross-hairs of this new technology - which is a great thing. Advertisers might get excited again about newspapers if the industry can deliver 100% color capacity and variable data content and ads. Advertisers just might be interested in pin point accuracy of ads that match demographics of a neighborhood or an individual subscriber profile. Advertiser might be willing to pay higher ad rates to deliver ad content that they know will be realevant to the consumer.

Looking back 25 years, we easily realize the evolution that color brought to the newspaper markets. Today, digital web presses revealed at DRUPA is likely the next generation of technology that will deliver the next evolution of the newspaper to the consumer market.

Since the early 1900's, newspapers have been produced on high speed web presses that crank out thosands of the same product and have only gotten faster as the newspaper industry rolled into the 21st century. The newspaper industry's transition to color in the 1980's also redefined the industry and newspapers continue to add capacity or reconfigure equipment to deliver full-color advertising.

Technology today is adding a relatively new capability for digital web printing; variable content. Variable data printing isn't exactly new, but the expansion of the forms and statement printing platforms into digital web printing capabilities for newspapers and commercial printers is new.

The newspaper market is squarely in the cross-hairs of this new technology - which is a great thing. Advertisers might get excited again about newspapers if the industry can deliver 100% color capacity and variable data content and ads. Advertisers just might be interested in pin point accuracy of ads that match demographics of a neighborhood or an individual subscriber profile. Advertiser might be willing to pay higher ad rates to deliver ad content that they know will be realevant to the consumer.

Looking back 25 years, we easily realize the evolution that color brought to the newspaper markets. Today, digital web presses revealed at DRUPA is likely the next generation of technology that will deliver the next evolution of the newspaper to the consumer market.

Tuesday, June 10, 2008

Digital Media: Building a Multi-media Platform

The print newspaper is now only one of the media platforms to deliver content to consumers. Today, information is disseminated through print, Internet, RSS feeds, hand-held devices and a variety of other wireless devices.

NAA is working on a project to quickly build the digital media platform to deliver multi-media content to consumers - but significant changes are needed to make this integration a reality. For years, newspapers have operated on a single-product workflow. In the changing multi-media environment, there are several workflows and products to disseminate information - so the future media delivery platform will rely on a content database, with articles, photos and ads (all content) dynamically coded to be delivered through all delivery methods. Several suppliers and universities have created content based content management products and dissemination models that will deliver content from a centralized database.

Today, targeting the customer is based widely on demographics and social statistics for specific areas or age groups. But customer specific media content delivery, which is based on a specific consumer's interests and demographics, does not exist. The piece of the media delivery model that needs to built is the Customer Profile Database; where customers are invited to create interest profiles and register online for topic specific delivery of content. For example, if you are a SF Giants fan and want in-depth stories and analysis throughout the season; then that's the content that is sent to you. The customer chooses the topics, content sources and information delivery method.

The advantage to the newspaper/media company is the ability to deliver targeted ad content precisely to consumers based on their customer profile of interests. The customer profile will contain broad interests and activities; ie. do you own a dog or cat. If the consumer owns a dog, than specific ads for dog food or dog products will be sent to the consumer, not cat products. The accuracy and depth of the Customer Profile Database is endless - do they own a European or American car, the age of their kids, business interests and investments, outdoor activities, etc. Consumers can also specify the type or source for content - choosing only national news or only sports, or only specific news sources. The creation of multi-branded newspaper or digital media is coming. A customer might want their local home town news, USA Today sports and Wall Street Journal business news. The technology is evolving to deliver specific content - so newspaper/media companies will need to think about how to offer story or section specific content bundled with content from other sources.

So look at this as the first step to individualized content delivery, where you can tailor ads and interest specific content from multiple sources into a single individualized newspaper, web-page, or RSS feed.

NAA is working on a project to quickly build the digital media platform to deliver multi-media content to consumers - but significant changes are needed to make this integration a reality. For years, newspapers have operated on a single-product workflow. In the changing multi-media environment, there are several workflows and products to disseminate information - so the future media delivery platform will rely on a content database, with articles, photos and ads (all content) dynamically coded to be delivered through all delivery methods. Several suppliers and universities have created content based content management products and dissemination models that will deliver content from a centralized database.

Today, targeting the customer is based widely on demographics and social statistics for specific areas or age groups. But customer specific media content delivery, which is based on a specific consumer's interests and demographics, does not exist. The piece of the media delivery model that needs to built is the Customer Profile Database; where customers are invited to create interest profiles and register online for topic specific delivery of content. For example, if you are a SF Giants fan and want in-depth stories and analysis throughout the season; then that's the content that is sent to you. The customer chooses the topics, content sources and information delivery method.

The advantage to the newspaper/media company is the ability to deliver targeted ad content precisely to consumers based on their customer profile of interests. The customer profile will contain broad interests and activities; ie. do you own a dog or cat. If the consumer owns a dog, than specific ads for dog food or dog products will be sent to the consumer, not cat products. The accuracy and depth of the Customer Profile Database is endless - do they own a European or American car, the age of their kids, business interests and investments, outdoor activities, etc. Consumers can also specify the type or source for content - choosing only national news or only sports, or only specific news sources. The creation of multi-branded newspaper or digital media is coming. A customer might want their local home town news, USA Today sports and Wall Street Journal business news. The technology is evolving to deliver specific content - so newspaper/media companies will need to think about how to offer story or section specific content bundled with content from other sources.

So look at this as the first step to individualized content delivery, where you can tailor ads and interest specific content from multiple sources into a single individualized newspaper, web-page, or RSS feed.

Monday, June 9, 2008

Pressroom Performance Metrics

When you're talking about Pressroom or Inserting production - do you know how well your operation is performing? For many newspapers, Production's performance is evaluated only on delivering the newspaper on-time - also known as the press off-time, last truck out time or stop time. Independent of what you call it, making the newspaper delivery time will likely keep the Publisher satisfied until next year's budget cycle, but isn't a guarantee that the production process is efficient.

There are many times that the operation is not under deadline pressure or has a longer than necessary production window. If you're not careful, the production performance can shift into "cruise" to fill the production window, but this also reduces efficiency. Running the equipment at a slower than rated speed isn't giving the press a 'rest' or is any easier on the machinery - it's simply less efficient and increases production costs.

In today's newspaper industry environment, getting the most out of your operation is critical and tracking operating performance is essential to maximizing efficiency.

The basic benchmarks for any production operation is make-ready time, overall waste percentage, start-up waste count, running speed, and net speed. All of these variables can be measured and tracked to determine the efficiency of the pressroom.

A key evaluation point in a high performance pressroom is core waste - how much paper is on the core after a paster. Obviously core breaks and running off the core is not acceptable, but so is having 1" of newsprint on the core. The reel and paster adjustments should be fine-tuned to have approx. 1/4" of newsprint remaining on the core; otherwise it's like leaving dollar bills wrapped on every core.

Another important evaluation of your pressroom is start-up waste; the number of papers it takes to get a sellable copy off the press. If that number is 500 or 2500; start-up waste should be a continuous improvement initiative. The first question is to ask why was the first copy acceptable and the previous copy wasn't. Having the press-crew evaluate the last bad copy will enlighten them, and management, to issues and opportunities for improvement. Was the last bad copy rejected because of ink density - then investment in ink levelers or CIP4 ink presets might be easy ROI, or was the problem registration - then finding the root cause of the variation and upgrading reel stands or nips/trolleys might bring color into register faster and reduce start-up waste.

Not all jobs are created equal. If it's the press configuration or the number/size of inserts running in the packaging center; all jobs should have a difficulty factor. This is job specific performance targets based on history. If you're running all full-rolls on press, without angle bars or other special web moves, that the press should be able to run faster than if you have 1/4 rolls and angle-bars moving the web. So to maximize efficiency, establish performance targets for specific types of jobs.

So even if the newspaper is delivered on-time; the challenge in today's newspaper market is to establish detailed production performance metrics to find additional efficiency and reduce costs.

There are many times that the operation is not under deadline pressure or has a longer than necessary production window. If you're not careful, the production performance can shift into "cruise" to fill the production window, but this also reduces efficiency. Running the equipment at a slower than rated speed isn't giving the press a 'rest' or is any easier on the machinery - it's simply less efficient and increases production costs.

In today's newspaper industry environment, getting the most out of your operation is critical and tracking operating performance is essential to maximizing efficiency.

The basic benchmarks for any production operation is make-ready time, overall waste percentage, start-up waste count, running speed, and net speed. All of these variables can be measured and tracked to determine the efficiency of the pressroom.

A key evaluation point in a high performance pressroom is core waste - how much paper is on the core after a paster. Obviously core breaks and running off the core is not acceptable, but so is having 1" of newsprint on the core. The reel and paster adjustments should be fine-tuned to have approx. 1/4" of newsprint remaining on the core; otherwise it's like leaving dollar bills wrapped on every core.

Another important evaluation of your pressroom is start-up waste; the number of papers it takes to get a sellable copy off the press. If that number is 500 or 2500; start-up waste should be a continuous improvement initiative. The first question is to ask why was the first copy acceptable and the previous copy wasn't. Having the press-crew evaluate the last bad copy will enlighten them, and management, to issues and opportunities for improvement. Was the last bad copy rejected because of ink density - then investment in ink levelers or CIP4 ink presets might be easy ROI, or was the problem registration - then finding the root cause of the variation and upgrading reel stands or nips/trolleys might bring color into register faster and reduce start-up waste.

Not all jobs are created equal. If it's the press configuration or the number/size of inserts running in the packaging center; all jobs should have a difficulty factor. This is job specific performance targets based on history. If you're running all full-rolls on press, without angle bars or other special web moves, that the press should be able to run faster than if you have 1/4 rolls and angle-bars moving the web. So to maximize efficiency, establish performance targets for specific types of jobs.

So even if the newspaper is delivered on-time; the challenge in today's newspaper market is to establish detailed production performance metrics to find additional efficiency and reduce costs.

Friday, June 6, 2008

LEAN & Six-Sigma Tools for Newspapers

Today, the newspaper industry is looking for anything and everything to improve efficiency and reduce costs to survive. Unfortunately, the typical approach is cutting staff and quality of goods; not looking at improving processes within the newspaper. The multi-media transition for the newspaper industry is begging for process improvements to lead the industry change. The answer is outside the traditional newspaper operation - there are two very important quality tools that can optimize the transition and reduce costs: LEAN and Six-Sigma

What are they?

LEAN: Root out waste so you can accelerate production.

Six-Sigma: Near-perfection is possible . . . so aim for it.

LEAN focuses on speed and efficiency, reducing cycle time, and focus on customer needs to define product value. To achieve such acceleration, LEAN finds waste and plans how to eliminate it. I.e., define optimal manufacturing processes to minimize production time and implements changes to improve efficiency. Waste is defined as non-value-added work, and there are eight types: wasted human talent, defects, sitting inventory, overproduction, waiting time, motion, transportation and waste processing—the time required to handle the consequences of the types of waste. LEAN uses specific tools to analyze process flow and delay times for each activity along the way. The results amassed provide a means of quantifying and eliminating the costs woven into the business complexities.

Downside: LEAN will not bring a process under statistical control.

Six-Sigma is all about manufacturing accuracy through a data-driven, problem-solving method to eliminate product defects identified by customers in ways that are sustainable. It involves a comprehensive set of quality-improvement tools, within a framework or set of rules and guidelines that has already shown itself to be effective at problem solving. Six-Sigma has been used to stabilize manufacturing operations by eliminating defects, produce products with higher reliability, and get new products to market faster. Applying Six-Sigma methodology is a complex process, one that requires internal changes in infrastructure to create an environment for obtaining results that are sustainable over time. The well-known Six-Sigma production standard is for no more than 3.4 defects per million product units. It’s a high target, and companies that apply Six-Sigma techniques correctly are meeting it routinely.

Downside: By itself, Six-Sigma cannot effect dramatic improvements in process speed or reduce invested capital.

United, the two tools quantify and eliminate the cost of complexity. Combining the two methodologies, LEAN Six-Sigma Manufacturing sets up interactions that reinforce each other. Percentage gains in Return on Investment Capital (ROIC) come much faster if LEAN and Six-Sigma are implemented together. “Just speed” or “just quality” will not produce the balanced results that enable an organization to ratchet up quality to a level defined by customers within a set time period. Industry leaders, such as Toyota and Motorola, have used LEAN Six-Sigma tools successfully to focus on customer needs and propel them to leadership positions in their respective industries. At the core, LEAN Six-Sigma is a data-based structure for making reality based decisions and eliminating waste out of the processes required to deliver news to the reader.

LEAN Six-Sigma Manufacturing Within the Industry

Many trends in the industry embody LEAN Six-Sigma Manufacturing principles, whether intentionally or not:

LEAN

1. Outsource functions for efficiency, cost reduction and better customer service.

2. Reduce the geographic area where papers are distributed, thereby reducing circulation, newsprint and transportation expenses, and allowing more targeted focus on the stated needs of core audiences.

3. Using common operational systems and data bases to optimize communication between departments.

SIX-SIGMA

1. Participate in the International Color Quality Club program and qualify for the SNAP Certificate to tighten and test printing competencies.

2. Participate in the ABC Insert Verification Process, as the audit program already has demonstrated that the industry is nearing 98-percent accuracy, indicating careful control of insertion processes.

3. Use production run data to track production efficiency and identify sources of downtime.

4. Determine the organization’s carbon footprint.

LEAN + SIX-SIGMA

1. Employ ink presets so that both ink and time are saved, newsprint waste is reduced, and product quality rises.

2. Use ICC profiles and GCR in your photo editing process to optimize quality and consistency of color photos.

All these suggestions will ultimately make your operation more efficient and cost effective, but more importantly it will refocus your management team and staff to look for answers and improvements beyond just cost cutting.

What are they?

LEAN: Root out waste so you can accelerate production.

Six-Sigma: Near-perfection is possible . . . so aim for it.

LEAN focuses on speed and efficiency, reducing cycle time, and focus on customer needs to define product value. To achieve such acceleration, LEAN finds waste and plans how to eliminate it. I.e., define optimal manufacturing processes to minimize production time and implements changes to improve efficiency. Waste is defined as non-value-added work, and there are eight types: wasted human talent, defects, sitting inventory, overproduction, waiting time, motion, transportation and waste processing—the time required to handle the consequences of the types of waste. LEAN uses specific tools to analyze process flow and delay times for each activity along the way. The results amassed provide a means of quantifying and eliminating the costs woven into the business complexities.

Downside: LEAN will not bring a process under statistical control.

Six-Sigma is all about manufacturing accuracy through a data-driven, problem-solving method to eliminate product defects identified by customers in ways that are sustainable. It involves a comprehensive set of quality-improvement tools, within a framework or set of rules and guidelines that has already shown itself to be effective at problem solving. Six-Sigma has been used to stabilize manufacturing operations by eliminating defects, produce products with higher reliability, and get new products to market faster. Applying Six-Sigma methodology is a complex process, one that requires internal changes in infrastructure to create an environment for obtaining results that are sustainable over time. The well-known Six-Sigma production standard is for no more than 3.4 defects per million product units. It’s a high target, and companies that apply Six-Sigma techniques correctly are meeting it routinely.

Downside: By itself, Six-Sigma cannot effect dramatic improvements in process speed or reduce invested capital.

United, the two tools quantify and eliminate the cost of complexity. Combining the two methodologies, LEAN Six-Sigma Manufacturing sets up interactions that reinforce each other. Percentage gains in Return on Investment Capital (ROIC) come much faster if LEAN and Six-Sigma are implemented together. “Just speed” or “just quality” will not produce the balanced results that enable an organization to ratchet up quality to a level defined by customers within a set time period. Industry leaders, such as Toyota and Motorola, have used LEAN Six-Sigma tools successfully to focus on customer needs and propel them to leadership positions in their respective industries. At the core, LEAN Six-Sigma is a data-based structure for making reality based decisions and eliminating waste out of the processes required to deliver news to the reader.

LEAN Six-Sigma Manufacturing Within the Industry

Many trends in the industry embody LEAN Six-Sigma Manufacturing principles, whether intentionally or not:

LEAN

1. Outsource functions for efficiency, cost reduction and better customer service.

2. Reduce the geographic area where papers are distributed, thereby reducing circulation, newsprint and transportation expenses, and allowing more targeted focus on the stated needs of core audiences.

3. Using common operational systems and data bases to optimize communication between departments.

SIX-SIGMA

1. Participate in the International Color Quality Club program and qualify for the SNAP Certificate to tighten and test printing competencies.

2. Participate in the ABC Insert Verification Process, as the audit program already has demonstrated that the industry is nearing 98-percent accuracy, indicating careful control of insertion processes.

3. Use production run data to track production efficiency and identify sources of downtime.

4. Determine the organization’s carbon footprint.

LEAN + SIX-SIGMA

1. Employ ink presets so that both ink and time are saved, newsprint waste is reduced, and product quality rises.

2. Use ICC profiles and GCR in your photo editing process to optimize quality and consistency of color photos.

All these suggestions will ultimately make your operation more efficient and cost effective, but more importantly it will refocus your management team and staff to look for answers and improvements beyond just cost cutting.

Subscribe to:

Comments (Atom)